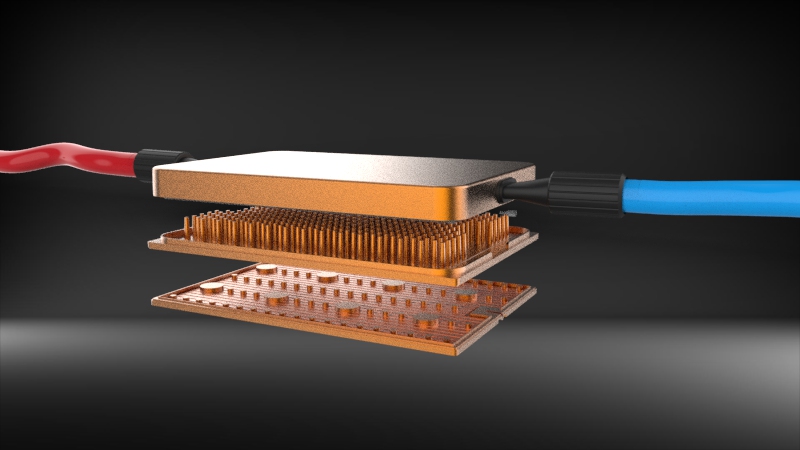

IHS application

Integrated heat spreader

Integrated Heat Spreader (IHS) is a heat dissipation technology used for semiconductor devices (such as central processing units or graphics processors). The IHS is usually a metal cover mounted directly on the surface of the chip to evenly disperse and conduct heat. This helps improve heat dissipation and protects the chip from damage.

In computer hardware, IHS is widely used in components such as central processing units (CPUs) and graphics processing units (GPUs). They help transfer heat to cooling solutions such as radiators and fans more efficiently. The use of integrated heat sinks can improve the performance and reliability of the hardware and prevent damage caused by overheating.

Characteristic 1

A metal cover, mounted directly on the surface of the chip, serves to evenly distribute and conduct heat.

Characteristic 2

Helps transfer heat more efficiently to cooling solutions such as radiators and fans.

Characteristic 3

Helps transfer heat more efficiently to cooling solutions such as radiators and fans.

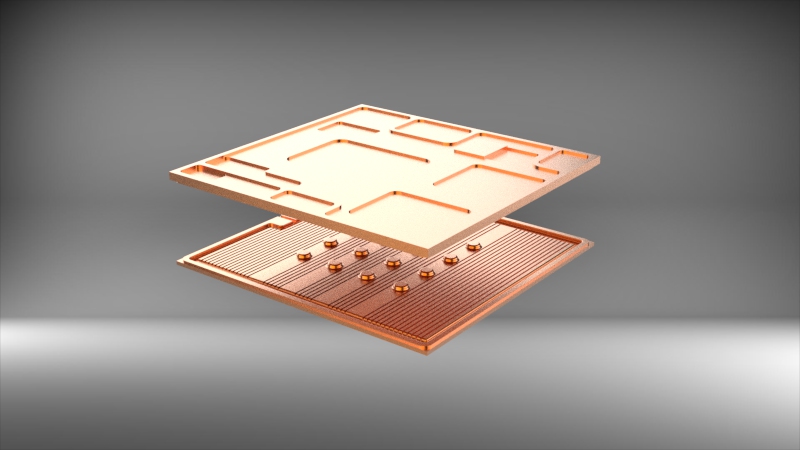

STIM application

Solder thermal interface material

Thermal interface material (Solder Thermal Interface Material) is a material used to effectively conduct heat energy and fill the small gaps between parts. These materials are commonly used in the manufacture of electronic components, particularly in semiconductor devices and electronic devices. The main function of welding thermal interface materials is to improve the efficiency of heat transfer between components, thereby maintaining the proper operating temperature of the components and preventing possible damage caused by overheating.

These materials are usually made of metal alloys or other highly thermally conductive materials to ensure good thermal conductivity. When assembling electronic components, solder thermal interface materials can be applied between the component and a heat sink, heat sink, or other heat dissipation device to ensure effective heat dissipation..

Characteristic 1

The main function of thermal interface materials is to improve the efficiency of heat transfer between components, thereby maintaining the proper operating temperature of the components and preventing possible damage caused by overheating.

Characteristic 2

Materials are usually made of metal alloys or other highly thermally conductive materials to ensure good thermal conductivity.

Characteristic 3

When assembling electronic components, solder thermal interface materials can be applied between the component and a heat sink, heat sink, or other heat dissipation device to ensure effective heat dissipation.